EBB: ElectroBiorefineries and Biosyntheses

Platform Project - PP4.1

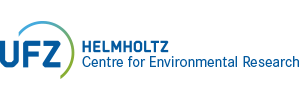

The platform project ElectroBiorefineries & Biosyntheses (EBB) aims to tap and tame nature’s resources and concepts for the sustainable production of chemicals and energy carriers. EBB focuses on recovering CO2 and efficient resource use, especially renewables, by next-generation biological and chemical conversion processes to provide the foundation for a circular economy. The latter excludes H2 that is considered in the platform project HYPRO.

Within EBB, a whole arsenal of expertise in microbiology, systems and synthetic biology, biochemistry, organic chemistry, reaction, reactor engineering, and process engineering is interweaved. This network allows following different production pathways that share one common goal: Identifying, developing, and designing as well as engineering methods, technologies, and processes to promote a circular biobased economy. To achieve this goal, scientists in EBB are, on the one hand utilizing non-living systems including enzymes and other cellular components under (initially) well-defined conditions, as well as chemical reactions, especially electrochemical synthesis. On the other hand, mainly anaerobic and electroactive microorganisms in pure cultures, as well as synthetic, semi-natural, and open mixed cultures, are exploited for biosynthesis. These conversion processes are researched from nano to pilot scale. Thereby the scientific activities and developments within EBB are unified for the sustainable processing of diverse feedstock into a spectrum of value-added products, including, for instance, organic and fatty acids, alcohols, aromatics, and aliphatic hydrocarbons.

With all its endeavors, EBB will contribute to the deliverables of the Topic 7 of "Changing Earth - Sustaining our Future".

Workpackage 1 – (Bio) Chemical Synthesis

Drawing: T. Rohwerder, UFZ

Catalysts and reactions for a sustainable industry

Drawing: T. Rohwerder, UFZ

Catalysts and reactions for a sustainable industry

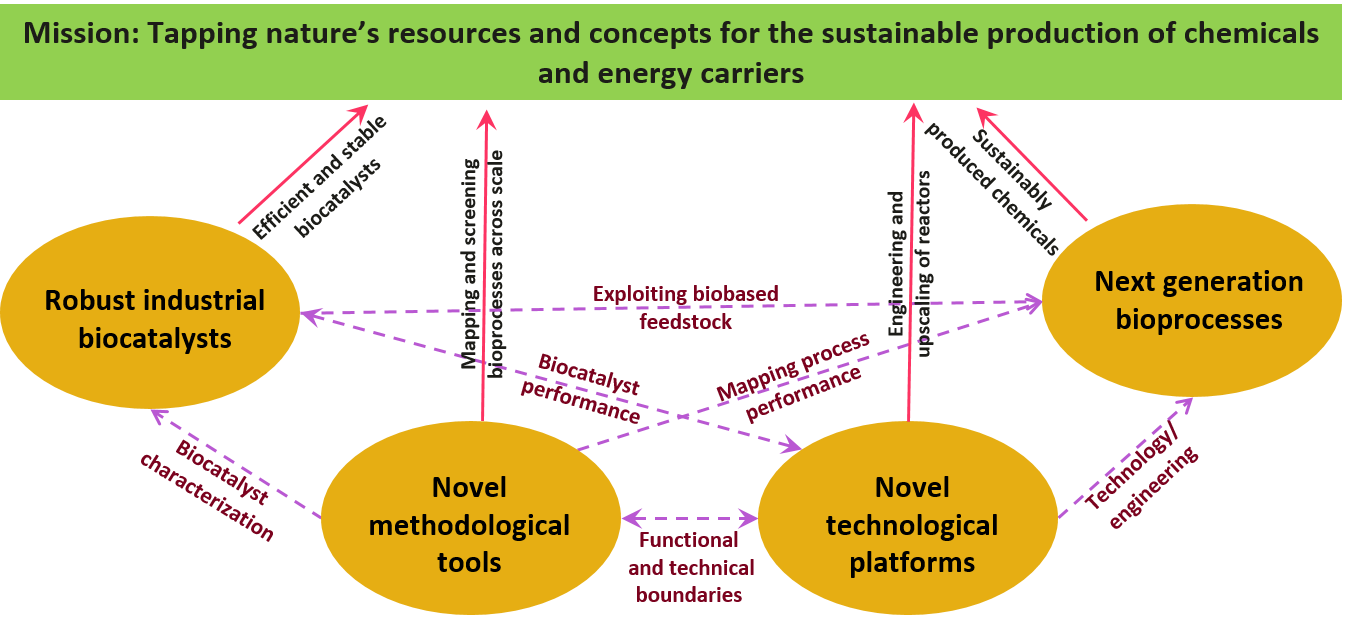

Within the platform project ElectroBiorefineries & Biosyntheses (EBB), the WP1 “(Bio) Chemical synthesis” is focused on research lines that utilize non-living systems, including enzyme solutions, immobilized enzymes, and other cellular components under (initially) well-defined conditions, as well as abiotic chemical catalysts and associated reactions, e.g., electrode reactions for the production of chemicals and/or energy carriers.

The WP1 possesses a multidisciplinary approach for replacing fossil-based synthesis with sustainable bioprocesses and recycling routes. Here, different technologies and processes are to be developed encompassing (bio)chemical catalytic and multi-physical models for the thermodynamic assessment of hydrolytic and electrobiotechnological processes, electrochemical reactor design and assessment, as well as electrochemical hydrogenations and hydrodeoxygenations of biomass. In addition, structure-guided rational design and directed evolution approaches are employed to change the specificity of enzymes towards novel synthesis reactions and pathways.

Our tasks:

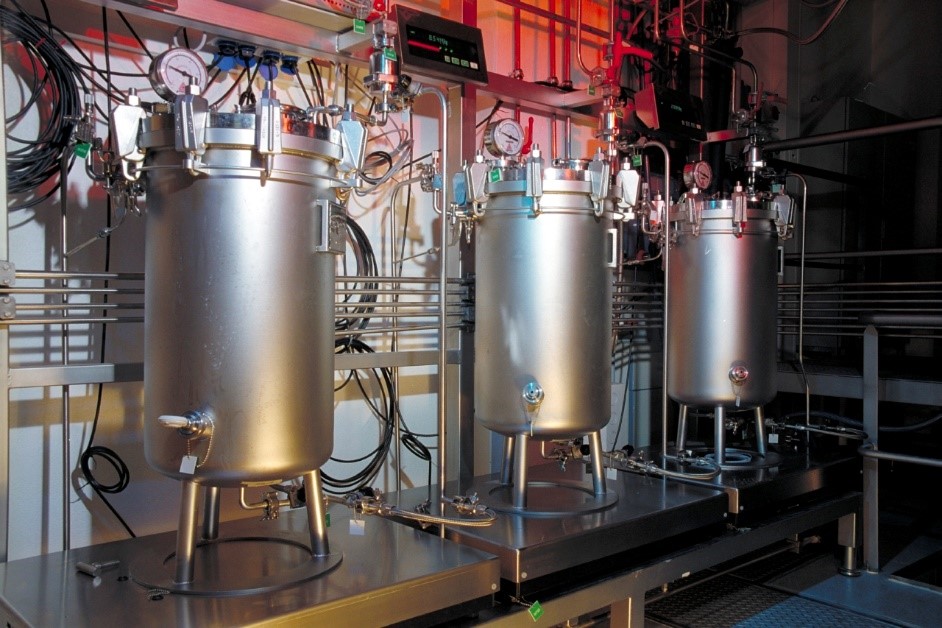

- Development and up-scaling of electrobioreactors to TRL 6-7

- Designing new metabolic pathways for C1 assimilation and synthesis of building block chemicals

- Development of a thermodynamic model for the enzymatic hydrolysis involved in polyethylene terephthalate (PET) recycling

- Developing processes based on electrochemical hydrogenation and hydrodeoxygenation for upgrading organic feedstock into value added chemicals that can be fed into existing production lines

- Developing an online processes (i.e. integrated platforms) for interweaving electrode-driven and microbial synthesis

Contact persons

Workpackage 2 – Pure Cultures

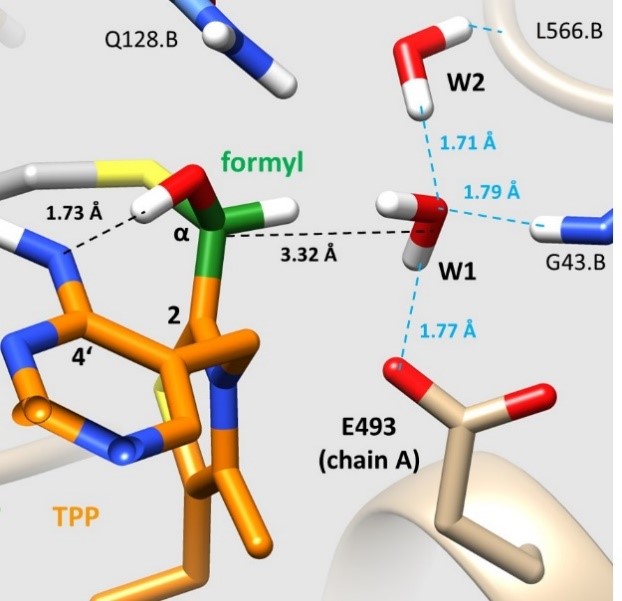

Photo: André Künzelmann/UFZ

In the platform project ElectroBiorefineries & Biosyntheses (EBB), the WP2 “Pure Cultures” focuses on a variety of microorganisms and processes utilized for sustainable production of chemicals and energy carriers. For example, the investigation and rational engineering of electrode-driven cellular metabolism as well as metalloproteins in bioelectrochemical systems. Furthermore, the aim is to provide novel robust platform organisms and strains for biotechnological approaches (for instance, solvent-tolerant Pseudomonas species or Yarrowia lipolytica) to produce chemicals from waste materials by-products and wastewater. In addition, the investigation of economically sound and sustainable processes, like steroid hydroxylation by recombinant E. coli strains and product formation from algae-derived glycolate, are also part of the WP2. Corresponding qualitative and quantitative analytical methodologies for the geno- and phenotyping of microorganisms are developed.

Photo: André Künzelmann/UFZ

In the platform project ElectroBiorefineries & Biosyntheses (EBB), the WP2 “Pure Cultures” focuses on a variety of microorganisms and processes utilized for sustainable production of chemicals and energy carriers. For example, the investigation and rational engineering of electrode-driven cellular metabolism as well as metalloproteins in bioelectrochemical systems. Furthermore, the aim is to provide novel robust platform organisms and strains for biotechnological approaches (for instance, solvent-tolerant Pseudomonas species or Yarrowia lipolytica) to produce chemicals from waste materials by-products and wastewater. In addition, the investigation of economically sound and sustainable processes, like steroid hydroxylation by recombinant E. coli strains and product formation from algae-derived glycolate, are also part of the WP2. Corresponding qualitative and quantitative analytical methodologies for the geno- and phenotyping of microorganisms are developed.

Our tasks:

- Elucidation and engineering of electrode-driven cellular metabolism in bioelectrochemical system with special focus on investigation of metalloproteins

- Providing novel tools to characterize microbial hosts in bioprocesses

- Novel robust platform organisms for biotechnological approaches

- Bioprocessing of waste for the production of chemicals in the context of a circular bioeconomy

- Product formation from algae-derived glycolate

Contact persons

Workpackage 3 – Mixed Cultures for Biosynthesis

Photo: André Künzelmann/UFZ

Humankind has been using mixed microbial cultures for a long time. Without any knowledge about microorganisms (actually not even knowing that they do exist), mixed cultures have been used to produce food and extend their shelf life. Well-known recent examples are biogas production and wastewater treatment.

Photo: André Künzelmann/UFZ

Humankind has been using mixed microbial cultures for a long time. Without any knowledge about microorganisms (actually not even knowing that they do exist), mixed cultures have been used to produce food and extend their shelf life. Well-known recent examples are biogas production and wastewater treatment.

Mixed microbial cultures consist of two or more organisms that may be members of different domains of life and whose exact identity is not necessarily known. In contrast to these imponderables, mixed microbial cultures exhibit several advantages. They can utilize various substrates in complex food webs and produce valuable products. Robustness against internal and external perturbations is a common characteristic. Moreover, energy- and time-consuming procedures such as sterilizing reactor vessels are unnecessary.

Therefore, within the platform project ElectroBiorefineries & Biosyntheses (EBB), the WP3 “Mixed Cultures” aims to identify, study, and steer mixed microbial cultures to develop advanced biotechnological processes. This will enable biobased feedstocks, CO2, and renewable energy to be tapped to produce chemicals and energy carriers.

Our tasks:

- Development of novel biotechnological processes, including phototrophic and electrobiotechnological approaches

- Identification and engineering of mixed microbial cultures for industrial applications

- Engineering and upscaling of reactors for next-generation bioprocesses

- Development of novel methodological tools to map and screen microbial processes across scales