ZeoPFAS - On-site regenerable zeolite adsorber for the removal of per- and polyfluorinated chemicals (PFAS) from wastewater

Numerous studies have shown that PFAS (perfluorinated and polyfluorinated alkyl substances) are hardly or not at all retained or degraded by conventional wastewater treatment processes, such as in municipal sewage treatment plants. Once released into the environment, PFAS spread ubiquitously through the earth's water cycle. In order to reduce the exposure of humans and the environment to PFAS as much as possible, measures to prevent new emissions, such as the discharge of PFAS-containing wastewater, must be taken. Compared to the regulation of drinking water, the discharge of industrial wastewater containing PFAS is currently hardly regulated. The guidelines are expected to be tightened in the future. This will greatly increase the demand for efficient technologies to remove persistent PFAS from contaminated water.

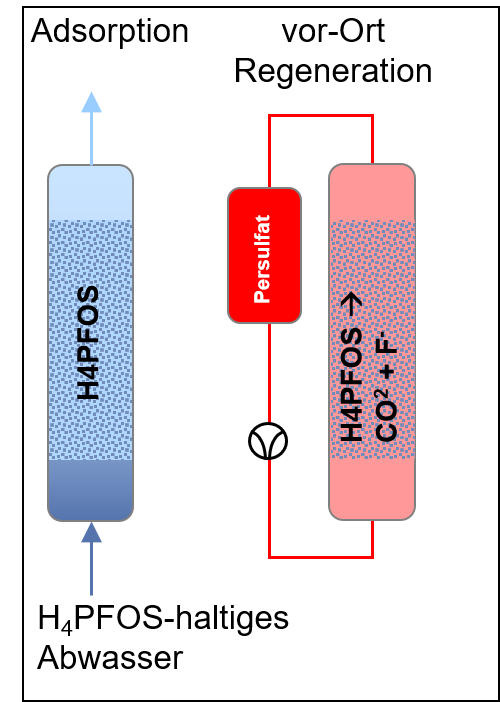

According to the current state of the art, activated carbon or ion exchangers are preferred for the separation of PFAS from wastewater, but these are sometimes less efficient and involve high disposal costs. In the ZeoPFAS project, we are developing a novel treatment strategy for PFAS-containing water. The process is based on the use of zeolites as on-site regenerable, stable and efficient inorganic adsorber materials. The combination of the accumulation of PFAS on the zeolite and the on-site regeneration of the loaded zeolite using heat-activated persulphate represents an effective treatment method for the purification of PFAS-containing (waste)water. Polyfluorinated compounds and perfluorinated carboxylic acids are completely mineralized by the sulphate radicals formed. The process is patented by the UFZ (Patent: EP3873659 (EU); US12017200 (USA).

The efficiency of the process is tested using the example of electroplating wastewater. Currently, the partially fluorinated 6:2 fluorotelomer sulfonic acid (H4PFOS) is mainly used as a wetting agent in the chromium plating process. As has already been observed for PFOS in the past, bleeding from the systems is to be expected even after the use of H4PFOS has been stopped, so that specific wastewater treatment will also be necessary for electroplating in the long term.

As part of the ZeoPFAS project, the degradation of H4PFOS is being investigated in batch and column tests on a laboratory scale using real site water from Winning Plastics - Diepersdorf GmbH and the operating conditions for the site are being optimized. A zeolite produced in Bitterfeld by Clariant Produkte GmbH is used for this purpose. In up-scaling, a pilot plant is operated on a technical scale in comparison to granular activated carbon (approx. 20 L adsorber volume each) and important performance parameters such as efficiency of the adsorption step, completeness of degradation in persulphate regeneration and performance of the regenerated zeolite in reuse are determined.

Contact person:

Dr. Ariette Schierz; Dr. Anett Georgi

Project partner:

UFZ- Department Technical Biogeochemistry

Winning Plastics – Diepersdorf GmbH

with the support of Clariant Produkte GmbH - Bitterfeld plant (zeolite supply) and eneotech Umwelt GmbH (plant construction)

Funding:Tranfun (UFZ internal funding programme)