Biogas upgrading

Introduction

Due to several advantages the importance of biogas production as part of the renewable energy technology spectrum has been increasing steadily for the last years. In contrast to other renewable energy sources like wind or solar biogas can be stored and transported very easily. For an efficient use of these potentials, biogas has to be fed into the already existing natural gas grid. In fact, this requires a certain quality of the biogas (e.g. in terms of maximum allowable water, sulfur dioxide and carbon dioxide concentrations) being equal to the natural gas standard. That’s why biogas upgrading is a key technology for its storage and transport and therefore for a sustainable green energy policy.

Main fields of research

Contacts

In addition to sulfur and carbon dioxide reduction water has to be removed from biogas to prevent condensation and therefore corrosion or freezing within the grid. While the first condensation-based drying step, the so called coarse drying, works efficiently up to mean moistures (dew point about 5°C), the fine drying step (dew point below -40°C) is up to now very energy intensive.

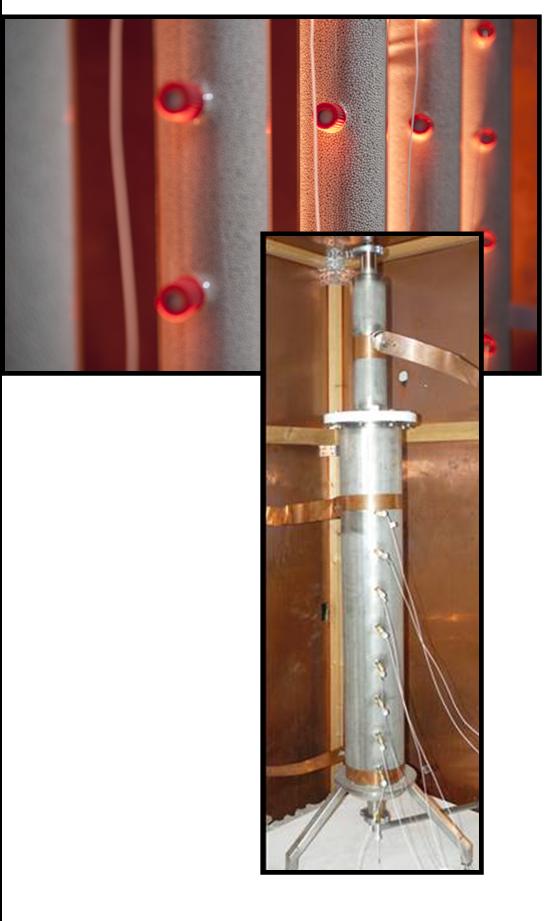

In cooperation with different companies and the Department of Bioenergy a new energy efficient fine drying technique is being developed. The innovative core of the new concept is the direct heating of a water adsorber by using radio waves. In a first step drying of the wet biogas takes place by adsorption of water on suitable adsorber materials like zeolites thereby reducing the water content to the necessary limit. After reaching the adsorption capacity the adsorption is followed by a second, a regeneration step, which is mostly realized by an heating process. Using conventional heating techniques, the low heat conductivity of the adsorber and the low heat capacity of a heating gas prevent an energy efficient and technically simple energy input. Due to the direct energy input leading to heat formation within the volume of the adsorber, heating techniques using electromagnetic waves can overcome these physical limitations.

Bases on this simple adsorption/desorption mechanism more complex fine drying regimes are tested using coupled mass-heat flow and selective radio wave heating effects. The goal of these more complex investigations is a continuously working fine drying process with only one packed bed. This optimization can further reduce energy consumption during the regeneration step. Studies focusing on adsorber materials and process engineering finally complete the research activities in this field.