Hydrothermal Carbonization HTC

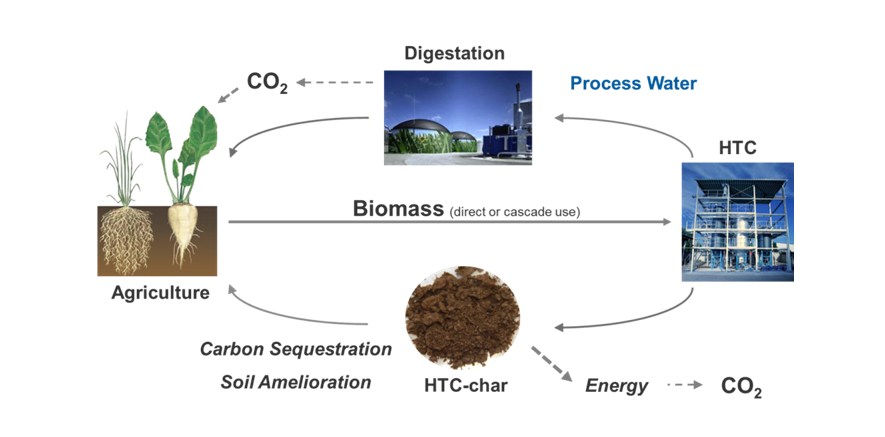

Hydrothermal Carbonization (HTC) is a process, in which biomass is heated in aqueous suspension to 180-250ºC under elevated pressure, thus in a closed system, to produce a solid biochar (the so-called HTC-char). The produced char is a bituminous coal like material that can be used as energy source but also for soil amelioration and as sorbent in water treatment processes. Parts of the organic carbon of the feedstock are dissolved after HTC in the process water, the concentration of which can amount to 5-30 gC/L depending on biomass source and process conditions, but only small amounts are released as gas, mainly CO2 (<5%). Various biogenic materials and waste biomasses have been used as feedstock, such as sewage sludge, municipal waste and spent grains.

We envision a cascade use of biomass with HTC as key-technology to upgrade (waste) biomass. It can be coupled to biogas production by using the digestates as feedstock for HTC and/or by utilization of the process waters as feedstock for methanogenesis. Carbon sequestration takes place when using the HTC-chars for soil amelioration.

A key challenge for the process optimization is represented by the process waters:

(a) utilization and treatment have to be optimized, and

(b) formation and fate of organic pollutants by using contaminated waste biomass has to be investigated.

Our research is tailored towards process optimization via basic research. For example a downstream wet-oxidative treatment has been described in our patent for HTC in a deep well reactor that is based on the Vertech-Technology. While in the influx stream reductive conditions are maintained to favor HTC, the downstream upward flow is treated with oxygen. The oxidative treatment can generate heat to promote the HTC process as well as reduce the chemical oxygen demand (COD) and dissolved organic carbon content of the process water. Furthermore, the fate of pesticides, pharmaceuticals, cosmetics and other organic pollutants (chlorinated aromatics, PAHs…) and their degradation products during HTC are investigated. Preliminary results have shown great potential of the HTC for the degradation of a wide array of organic substance groups. Moreover, we study the potential of HTC waters for the generation of biogas (methane) in collaboration with the DBFZ . At the UBZ , small scale field experiments are performed in parallel to study the HTC-chars as soil fertilizers.

Keywords:

- HTC of various biomass matrices (sewage sludge, distiller’s grains, invasive aquatic plants, etc.) and characterization of all product streams.

- Characterization, utilization and treatment of the HTC-process waters.

- Wet-oxidation of HTC-suspensions.

- Formation and fate of organic and inorganic pollutants during HTC.

Contacts:

Completed Projects:

- Project CARBOWERT is supported by funds of the Federal Ministry of Food, Agriculture and Consumer Protection (BMELV) based on a decision of the Parliament of the Federal Republic of Germany

- International Water Reasarch Alliance Saxony (IWAS) 2009 - 2012

Cooperation:

Publications:

- F.-D. Kopinke, H. Hildebrand, R. Köhler, I. Baskyr and J. Pörschmann

Verfahren und Reaktor zur hydrothermalen Karbonisierung von Biomassen im Tiefschacht-Reaktor und zur gleichzeitigen Nassoxidation der anfallenden Prozesswässer.

EP 2.206.688 A1 (2010) - B. Weiner, I. Baskyr, J. Poerschmann, F.-D. Kopinke

Potential of the hydrothermal carbonization process for the degradation of organic pollutants

Chemosphere, 92(2013) 674 - 680 - J. Poerschmann, I. Baskyr, B. Weiner, F.-D. Kopinke

Hydrothermal carbonization of olive mill wastewater

Bioresource Technology 133(2013) 581 - 588 - J. Poerschmann, B. Weiner, I. Baskyr

Organic compounds in olive mill wastewater and in solutions resulting from hydrothermal carbonization of the wastewater

Chemosphere in press