Department of Solar Materials Biotechnology (SOMA)

How can biotechnology contribute to the reduction of greenhouse gases in our atmosphere and to a decentralized energy supply? How can we produce energy sources and recyclables in an environmentally friendly and sustainable way from non-fossil resources? Which factors determine the efficiency and productivity of microorganisms as living catalysts and how can they product-oriented be maximized?

"The use of solar energy for the chemical or biological production of hydrogen is an attractive and environmentally friendly technological goal, but it is very demanding and still at the level of basic research. It is still unclear whether any of these strategies will ever become a practical application on a large scale. " (Bioenergy - Opportunities and Risks; (2012), Leopoldina).

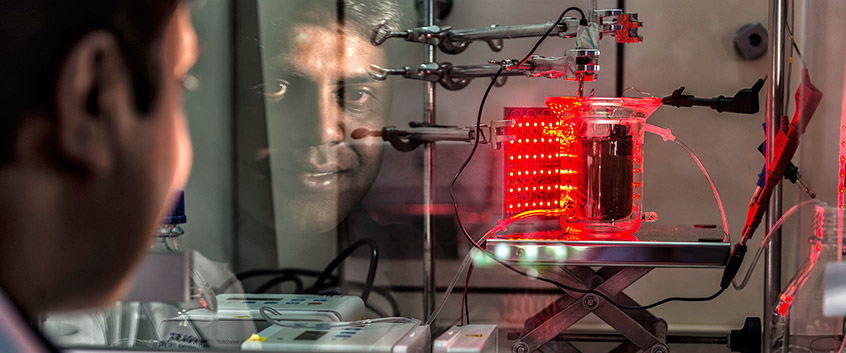

The Department of Solar Materials Biotechnology (SOMA) with currently three research groups "Molecular Biology of Cyanobacteria", "Photobiotechology" and "Microscale Analysis and Engineering" addresses this challenge with an integrated biotechnological approach that combines expertise from the system bio-(techno) logy, molecular biology, microbial physiology, biochemistry and process engineering. Based on many years of experience in biocatalyst and bioprocess design, we focus on the development of new biotechnology concepts based on the principle of "bioartificial photosynthesis". The concepts exploit the natural ability of photoautotrophic cyanobacteria to split water using solar energy and simultaneously assimilate the greenhouse gas CO2. As a result two attractive products are formed: hydrogen, which is intensively debated as an efficient source of energy in the future, and carbon intermediates, which can be environmentally friendly converted via (partly artificial) microbial metabolic pathways into various chemical compounds. These products are only produced in small quantities, or are directly converted further. In addition, the reaction systems are often very unstable. Our goal is to produce these products in technically relevant quantities and to develop scalable photo-capillary bioreactors. The ultimate goal is the technically controlled realization of the biochemical "short circuit" - the generation of hydrogen directly from water.

Achieving this goal requires a thorough understanding of the underlying biochemistry and cell physiology as biocatalysts and the determinants for catalytic efficiency. These basic research questions lead to a holistic understanding of the system and allow the design of procedural solutions to verify the results. This knowledge will be used to produce powerful biocatalysts and technically scalable manufacturing processes whose efficiency and sustainability can be quantified.