HTC and Sewchar

Research Objective

The studies within this framework (the cross-cutting theme “Development and Implementation of Technologies”) are focused on thermal approaches of waste biomass treatment, in which coal-like products are produced in aqueous media (hydrothermal carbonization - HTC) or via dry pyrolysis (e.g. the thermo-catalytic low-temperature conversion). Their potential to use biomass with simultaneous reduction of CO2- and pollutant emissions is investigated for their applicability in the model regions of IWAS and in Germany.

Methods, Models, Approaches

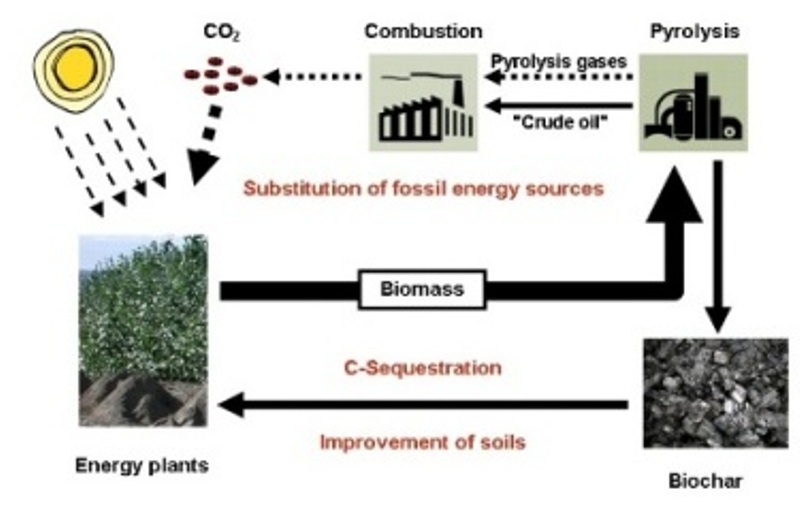

The thermo-chemical conversion of plant biomass proceeds under anaerobe conditions and produces solid carbon-enriched materials, the so called biochars. They allow carbon sequestration with simultaneous improvement of soil fertility when applied in agriculture or forestry. The gas and liquid products of the pyrolysis are employed as energy sources and can substitute fossil fuels. Applications of biochars themselves as fuel are also of great interest. A combination of such technologies and applications is called a Biochar-system (Fig 1).

The biochar systems show great potential for the use of materials from the waste management sector, for which nowadays no sustainable applications exist. This especially applies to sewage sludge from the communal water treatment plants. The thermal treatment simultaneously allows both the hygienization of the affected materials and the destruction of organic pollutants. Sewchar-systems can thus represent an important tool for an integrated water resource management in the residential water sector.

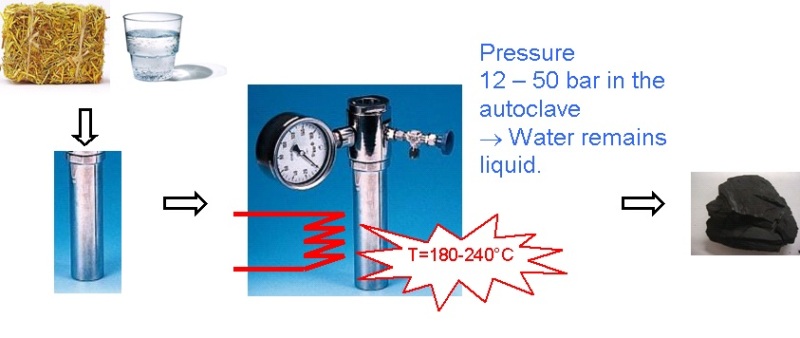

Whereas pyrolytic approaches, such as the thermo catalytic low-temperature conversion (Niedertemperaturkonvertierung, NTK) and the PYREG technology, aim at processing of dry (or pre-dried) materials, the hydrothermal carbonisation (HTC) allows a direct conversion of water-rich substrates. At the same time, the HTC process also improves the dewatering properties of the initial materials. Therefore, HTC seems to be well applicable to sewchar-systems. As compared to pyrolysis-based systems, there is so far a lack of knowledge about the applicability of HTC within biochar-oriented concepts. This relates to both the technology and the properties of the products and their effects on soil and plant growth.

The following experiments give a basis for further investigations.

Figure 1. The Biochar concept

Figure 2. Hydrothermal carbonization (HTC)

At the Department of Environmental Engineering of the UFZ, laboratory HTC experiments are carried out in autoclaves and mini-autoclaves (see Fig. 2, 3), in which reaction conditions are optimized for using various biomasses or, alternatively, for the degradation of pollutants. The feedstocks comprise, besides sewage sludge, brewer’s spent grain, sugar beet pulp, digestates from ethanol and methane producing plants, and artificial carbon sources (saccharose, paper). The experiments involve variation of temperature, duration of the reaction, catalysts, and also addition of reducing agents such as zero-valent iron. The HTC-waters are investigated by various chemical-analytical methods (primarily GC/MS). Furthermore, their purification was identified as a separate challenge, and it will be studied in future experiments.

Figure 3. Mini-autoclave for HTC experiments

The Center for Environmental Biotechnology of the UFZ investigates variations of the Sewchar-concept via comparative analysis of HTC and NTK products and their effects on pedological parameters and plant growth (Fig. 4).

Figure 4. Germination and plant growth in sewchars

Results

Our preliminary results show that the HTC process possesses a great potential for degrading organic pollutants occurring in sewage sludge and plant biomasses (Tab. 1).

Table 1. Destruction of selected pollutants at 200 °C for 16 h in aqueous solutions without addition of catalysts or carbon sources.

| Analyte | Degree of Destruction |

|---|---|

| Skatole | 99 % |

| Tetrabutyltin | 64 % |

| Bisphenole A | 50 % |

| Nonylphenole | 62 % |

| Atrazine | 100 % |

| Triallate | 100 % |

| 4,4’-DDT | 30 % |

| 2-Chlorphenole | 20 % |

| 1,2,4-Trichlorobenzene | 20 % |

Comparative analyses of NTK and HTC-chars and their effects on soils and plants show considerable differences. According to these results, HTC-chars possess phytotoxic properties which would make a pre-treatment necessary for agricultural and forestry applications. Despite the fact that HTC-systems are expected to have immanent advantages for the circulation of plant nutrients, especially with regard to the nitrogen found in high concentration in the waste water sector, greenhouse experiments with plant cultures point to a stronger improvement of the plant growth, when the NTK-materials are applied.

Several methods for the pre-treatment of HTC-chars are currently investigated. A technical concept for the HTC on industrial scale is being developed, aimed at both solving the technical challenges of continuously working HTC reactors and the treatment and recycling of the HTC-wastewaters.

On the basis of the results from the greenhouse experiments, studies are now conducted in order to reveal the long-term effects of the carbonized products from various feedstock substrates and conversion methods on soil and plant growth under open land conditions.

Researchers in Charge

Prof. Dr. Frank-Dieter Kopinke

Helmholtz Centre for Environmental Research

Department of Environmental Engineering

Permoserstrasse 15

04318 Leipzig

e-mail: ![]()

![]() frank-dieter.kopinke@ufz.de

frank-dieter.kopinke@ufz.de

Dr. Igor Baskyr

Helmholtz Centre for Environmental Research

Department of Environmental Engineering

Permoserstrasse 15

04318 Leipzig

e-mail: ![]()

![]() igor.baskyr@ufz.de

igor.baskyr@ufz.de

Dr. Jürgen Pörschmann

Helmholtz Centre for Environmental Research

Department of Environmental Engineering

Permoserstrasse 15

04318 Leipzig

e-mail: ![]()

![]() juergen.poerschmann@ufz.de

juergen.poerschmann@ufz.de

Dr. Barbara Weiner

Helmholtz Centre for Environmental Research

Department of Environmental Engineering

Permoserstrasse 15

04318 Leipzig

e-mail: ![]()

![]() barbara.weiner@ufz.de

barbara.weiner@ufz.de

Dr. Roland Arno Müller

Helmholtz Centre for Environmental Research

Centre for Environmental Biotechnology (UbZ)

Permoserstrasse 15

04318 Leipzig

e-mail: ![]()

![]() roland.mueller@ufz.de

roland.mueller@ufz.de

Dr. Christoph Fühner

Helmholtz Centre for Environmental Research

Centre for Environmental Biotechnology (UbZ)

Permoserstrasse 15

04318 Leipzig

e-mail: ![]()

![]() christoph.fuehner@ufz.de

christoph.fuehner@ufz.de

Supplementary Material (PDFs, Links)

Patent application:

F.-D. Kopinke, R. Köhler, H. Hildebrand, I. Baskyr, J. Pörschmann: Verfahren und Reaktor zur hydrothermalen Karbonisierung von Biomassen und zur Nassoxidation der anfallenden Reaktionswässer. DPA, Ref. No. 10 2010 062 833.6 (Applicant: UFZ).

.png)

.png)