Adsorptive-catalytic off gas cleaning

Introduction

Process steps removing volatile compounds from gases (e.g. industrial off gas, indoor air or other exhaust gas sources) are part of many technical processes in the area of chemical industry and environmental protection. Volatile organic compounds (VOC) being emitted by many production processes, waste treatment, livestock breeding or soil and ground water remediation can not be recovered efficiently and, therefore, have to be eliminated. For low and high VOC concentrations methods based on adsorption and on thermo-catalytic oxidation have already been established. Unfortunately, in the range of mid (typical between 0.1 and about 1 gC/m3) and fluctuating concentrations which are in particular typical for remediation processes efficient off gas cleaning methods are still missing.

Technical concept

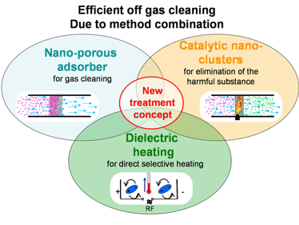

With the intention of closing this technical gap, an adsorptive-catalytic off gas cleaning concept is currently being developed. This concept combines the process steps adsorption, desorption and thermo-catalytic oxidation of VOC by means of a direct energy input using radio waves in only one packed bed that can be operated continuously.

The key feature of this new method is a selectively heated hot zone moving slowly through the packed bed during the regeneration phase. This effect is named thermo-chromatographic pulse (TCP). In this zone the previously adsorbed VOCs will be desorbed and directly oxidized into carbon dioxide and water due to a catalytically active component in this zone. Beside the simple construction this concept benefits from high energy efficiency due to an optimal use of the released oxidation heat. The oxidation heat contributes to heat the adjacent colder adsorber zone in the packed-bed thereby reducing the RW input power necessary to maintain the TCP. Hence, depending on boundary conditions and technical constraints also an autotherm regeneration can be realized.

Process description

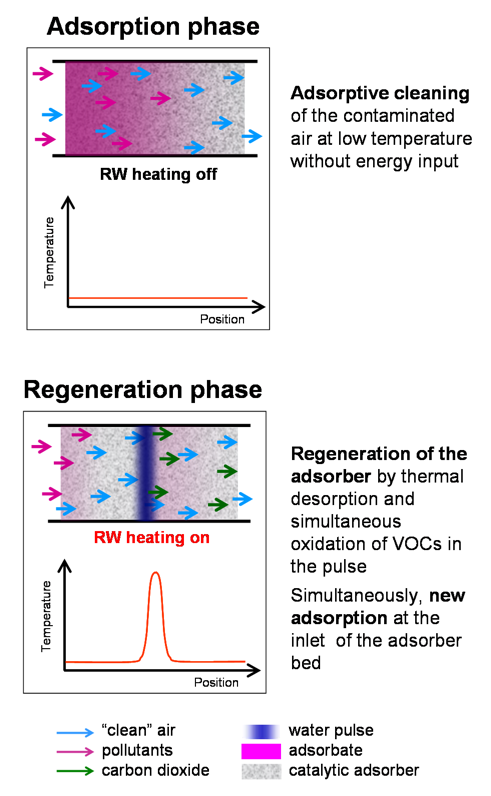

The new cleaning technology consisting of two phases (an adsorption phase and a regeneration phase) allows a continuous off gas cleaning within only one packed bed. During an adsorption phase the gas stream is cleaned by adsorption at ambient temperature without energy input. Before reaching the maximum adsorption capacity, the regeneration phase is initiated by switching on the radio frequency power and injecting a small amount of water acting as a coupling medium for electromagnetic waves. In the range of the adsorbed water the selective energy input leads to a selectively heated zone and, therefore, to desorption and oxidation of the adsorbed substances. Besides desorption and oxidation of VOC injected water is desorbed in the hot zone and moves together with the gas stream to the next cold and contaminated zone where it is adsorbed again. There, according to the characteristics of a TCP, the heating cycle starts again. In this manner the packed bed is progressively cleaned during regeneration. The continuous influx of pollutants (VOC) also during regeneration will be treated either by oxidation directly in the hot zone or with increasing cooling by adsorption on the already regenerated and cold packed bed close to the inlet. This approach ensures a continuous cleaning of gas streams in one single backed bed.

The new cleaning technology consisting of two phases (an adsorption phase and a regeneration phase) allows a continuous off gas cleaning within only one packed bed. During an adsorption phase the gas stream is cleaned by adsorption at ambient temperature without energy input. Before reaching the maximum adsorption capacity, the regeneration phase is initiated by switching on the radio frequency power and injecting a small amount of water acting as a coupling medium for electromagnetic waves. In the range of the adsorbed water the selective energy input leads to a selectively heated zone and, therefore, to desorption and oxidation of the adsorbed substances. Besides desorption and oxidation of VOC injected water is desorbed in the hot zone and moves together with the gas stream to the next cold and contaminated zone where it is adsorbed again. There, according to the characteristics of a TCP, the heating cycle starts again. In this manner the packed bed is progressively cleaned during regeneration. The continuous influx of pollutants (VOC) also during regeneration will be treated either by oxidation directly in the hot zone or with increasing cooling by adsorption on the already regenerated and cold packed bed close to the inlet. This approach ensures a continuous cleaning of gas streams in one single backed bed.