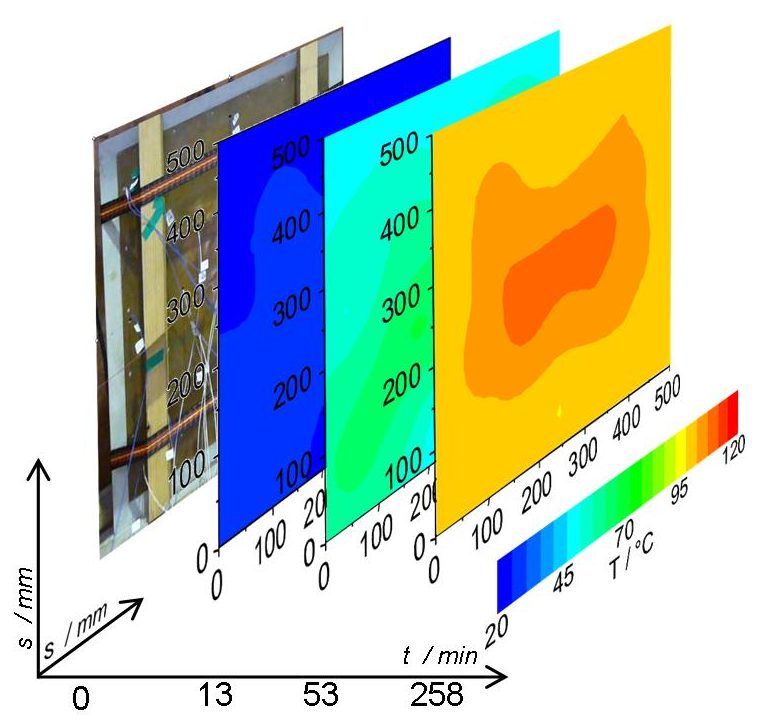

Radio wave induced brickwork heating

Drying, decontamination and chemical-free wood preservation

Reasons for wet brickwork (e.g. floodings, heavy rain water, leaky pipe systems…) are as manyfold as technologies for drying brickwork available on the market. For fast and efficient drying brickwork structures needs to be heated up in a controlled manner. Most established drying techniques working with infra red or hot air only warm up the surface of brickwork, so that their drying efficiencies strongly depend on diffusion processes at a relatively low temperature in the inner of the brickwork. But also microwave systems being the most common direct heating technique are characterised by maximum penetration depths from only 10 to 15 cm (depending on the material), which is not sufficient for bearing walls. Moreover, MW heating reaches its limits related to a reasonable energy input when the water content in the brickwork structure decreases.

Large penetration depths, homogeneous heating of large volumes, efficient energy conversion into heat within the brickwork, as well as a high flexibility in terms of achievable heating rates, maximum temperatures and heatable materials are the most important characteristics of the radio wave (RW) heating technology.

Motivated by these beneficial characteristics the RW heating for drying of brickwork is tested and optimized in the framework of an BMBF-Projekt “Innovation through the application of the RW heating technology in construction engineering” ( link ). Not only water but also harmful substances like fuel oil, solvents or wood preservation agents can be removed faster and more efficient from construction materials by controlled heating of these materials using radio waves. Mechanisms for the removal of chemicals from construction materials are similar to the ones governing thermal enhanced physical and chemical remediation processes ( link ).

In cooperation with the HTWK Leipzig (University of applied science) research is focused on the following aspects:

- RW heating of single construction materials and composite structures,

- Determination of technical requirements and process parameters for different applications,

- Suitability of RW heating for decontamination depending on chemical substances,

- Evaluation of RW heating for controlling and eliminating of wood destroying pests,

- Optimization of technical RW heating setup (e.g. electrodes) for different applications.

Further Information can be found here .